What Does an Oxy Fuel Cutting?

Oxy-fuel cutting process involves the use of fuel gases or liquid fuels such as gasoline or petrol, and oxygen to either weld or cut metals.

How Does An Oxy-Fuel Cutting Process Work in Malaysia

Oxy-fuel cutting process involves the use of fuel gases or liquid fuels such as gasoline or petrol, and oxygen to either weld or cut metals. French engineers Edmond Fouche and Charles Picard were the first to develop oxy-acetylene welding back in 1903.

The process uses pure oxygen instead of air in order to increase the flame temperature and allow localised melting of the workpiece material such as steel, in a room environment.

-

Common propane/air flame burns at about 2,250 K (1,980 °C; 3,590 °F)

-

Propane/air flame burns at about 2,526 K (2,253 °C; 4,087 °F)

-

Oxyhydrogen flame burns at 3,073 K (2,800 °C; 5,072 °F)

-

Acetylene/oxygen flame burns at about 3,773 K (3,500 °C; 6,332 °F)

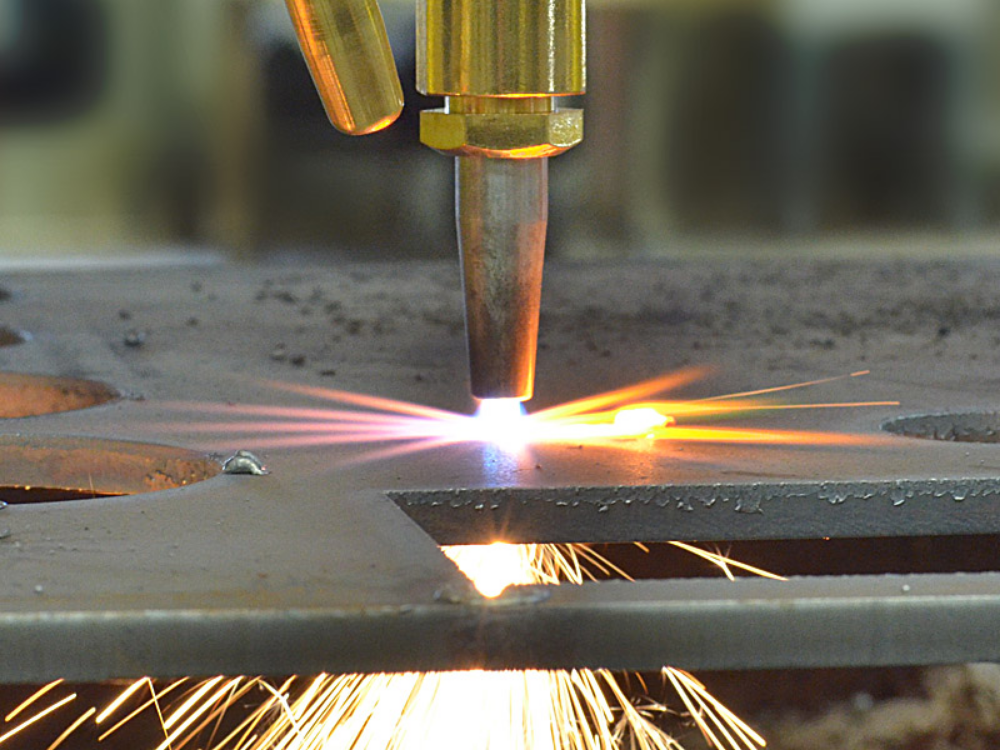

Before an oxy-fuel cutting process begins, the cutting torch has to preheat the steel to the ignition temperature. At a temperature of around 960°C depending on the type of alloy used, the steel will lose its protective properties against oxygen and still remain solid.

The pure oxygen is then distributed through the nozzle at the heated area. This delicate and high-pressure oxygen stream will change the pre-heated and unprotected steel into an oxidised liquid steel through an exothermic reaction.

This slag here has a lower melting point compared to the steel, hence the blowing of the liquid slag out of the cavity by the oxygen stream without impacting the non-oxidised solid steel. This exothermic reaction belongs to a continuous process and creates a cut as the torch moves. To keep this reaction ongoing, the cutting torch will keep the steel heated during cutting.

What Does an Oxy-Fuel Cut?

The oxy-fuel cutting process is made to cut steel with composition lower than .3% carbon. Mild steel comprises 98% iron, 1% manganese, carbon up to .3% and other elements alike in rather minimal amounts. Oxy-fuel cutting is not capable of cutting non-ferrous metals like aluminium, stainless, brass or copper. Elements including chromium, nickel, and molybdenum have the ability to cut steel through the oxy-fuel process. With that being said, manganese, silicon, phosphorus, and sulphur in normal amounts don’t generate much effects on the cutting process.